E-Mobility Thermal Management

- Home

- Industries

- E-Mobility Thermal Management

E-Mobility Thermal Management

Engineered Cooling for the Electrified Road Ahead

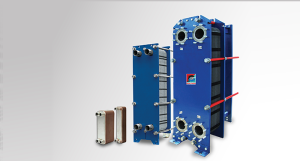

Lithium-ion (Li-Ion) batteries are highly sensitive to temperature fluctuations. Effective thermal management is critical to maximize energy storage capacity, improve charging and discharging performance, extend battery lifetime and prevent safety hazards, such as thermal runaway.

Too cold? Charging rates suffer, internal resistance rises. Too hot? Capacity degrades faster, and safety risks increase. Thermal runaway is a chain reaction where excessive heat causes battery cells to fail and release energy uncontrollably. This leads to rapid temperature rise in adjacent cells, posing a serious fire and explosion risk. The key to prevention lies in uniform cell temperature, active cooling, and robust system-level thermal design. Only a narrow temperature window ensures optimal battery operation.

Advanced e-mobility thermal design integrates not only the battery but the entire powertrain and cabin loop:

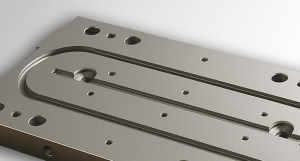

- Inverters and power electronics: Require active cooling to handle high switching frequencies and power densities.

- Electric motors: Cooling ensures consistent torque and avoids demagnetization under thermal stress.

- High-speed charging: Fast charging generates significant heat which needs to be managed.

- HVAC & Heat Pump systems: Critical for both cabin comfort and thermal loop efficiency, especially in cold climates.

Electrification is also gaining ground in off-highway sectors such as construction, mining, and agriculture. The benefits are clear:

- Lower local and global emissions

- Enhanced energy efficiency and power modulation

- Reduced Total Cost of Ownership (TCO) over lifecycle

These HD TMS require rugged thermal solutions that perform under vibration, dust, and variable loads – across extreme climates.