Marine

- Home

- Industries

- Marine

Marine

Built for Harsh Waters – Engineered for Performance

Marine thermal systems must perform flawlessly under continuous duty cycles, often in corrosive saltwater and variable water quality environments. Our marine heat exchangers are designed with a deep understanding of fluid dynamics, thermal loads, and long-term material behavior.

Key applications include:

- Main and Auxiliary Engine Cooling

- Lube Oil and Hydraulic Oil Cooling

- Freshwater Generation & HVAC Systems

- Chiller and Condenser Units

Material matters: copper, stainless steel, cupronickel, titanium, and beyond

The choice of material is not optional – it’s mission-critical.

- Copper-Nickel: Excellent resistance to seawater corrosion, erosion, and biofouling. Widely used in heat exchangers for marine engines and HVAC units.

- Titanium: Unmatched in corrosion resistance, ideal for ultra-aggressive brine conditions, desalination systems, and near-the-port environments.

Every application is evaluated for operating temperature, flow rate, water composition, and pressure drop, to select the right material and geometry not just to perform, but to endure.

Design optimization for marine applications

- Shell & Tube Heat Exchangers: Engineered for engine jacket cooling, lube oil systems, and liquid-liquid heat exchange.

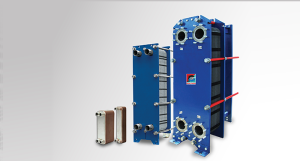

- Plate Heat Exchangers (PHEs): Compact and highly efficient, ideal for HVAC systems, chillers, and BWTS where space is a constraint.

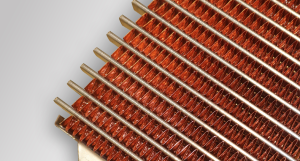

- Finned-Tube and Coil Units: For shipboard HVAC, refrigeration, and dehumidification systems available in custom geometries and coatings.

We support both newbuild and retrofit projects, providing complete thermal performance calculations, CFD simulations, and corrosion risk assessments.

Marine Applications We Serve

- Cargo ships and container vessels

- Offshore platforms and FPSOs

- Naval vessels and submarines

- Cruise ships and ferries

- Yachts and specialized marine research craft