Rail Transport Thermal Management

- Home

- Industries

- Rail Transport

Rail Transport Thermal Management

Reliable Cooling Across Altitudes, Speeds, and Power Platforms

Rail systems demand uncompromising thermal reliability whether powering through urban networks, high-speed corridors, or rugged terrains at extreme altitudes. Dolphin Manufacturing LLC provides cutting-edge cooling solutions tailored to the needs of modern and next-generation rail transport. From traditional internal combustion to electric, hybrid, and fuel cell drivetrains, our heat exchanger technologies ensure optimal thermal control under the harshest mechanical and environmental stresses.

Dolphin’s rail thermal management systems are built to endure:

- Extreme Thermal Cycling & Vibrational Loads

- High Power Densities (Up to 6000 HP)

- Variable Altitudes & Ambient Temperatures

- Continuous Operation with Long Maintenance Intervals

Every application is evaluated for operating temperature, flow rate, water composition, and pressure drop, to select the right material and geometry not just to perform, but to endure.

Application Covered

- Electric Trains: High-speed and regional electric trains rely on precise cooling for traction converters, transformers, and power electronics. Dolphin’s advanced heat exchangers ensure thermal stability for reliable and efficient propulsion.

- HVAC&R Systems for Passenger Coaches: Optimized climate control through reliable cooling of air conditioning units, compressors, and heat pumps enhancing passenger comfort and system efficiency in all climates.

- Diesel & Dual-Mode Locomotives: For heavy-duty diesel-electric locomotives with engine ratings up to 6000 HP, Dolphin supplies robust engine cooling packages, intercoolers, oil coolers, and water-to-boost intercoolers (WBICs), engineered to withstand sustained thermal and mechanical shocks.

- Alternative Fuel Locomotives: Dolphin supports emerging propulsion technologies, including fuel cell locomotives, LNG/CNG-powered designs, and hybrid systems, with custom thermal solutions designed for compact integration, modularity, and energy efficiency.

Key Technologies and Features

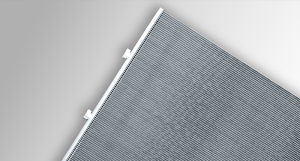

- Bar & Plate and Tube & Fin Aluminum Heat Exchangers: Lightweight, compact, and vibration-tolerant solutions ideal for electronic and traction component cooling.

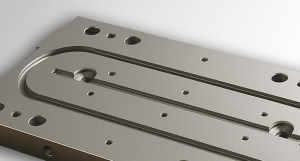

- WBICs (Water-Based Intercoolers): Delivering precise charge-air temperature control to support efficient combustion and emissions reduction in modern rail engines.

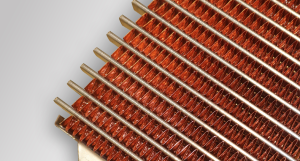

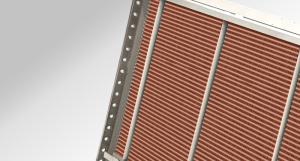

- Copper-Brass cooling Systems with Mechanical Expansion: Time-tested reliability and ease of repair for legacy and high-power engine platforms.

- Modular and Custom-Built Designs: Tailored to customer-specific installation constraints, thermal loads, and maintenance regimes.

Dolphin Manufacturing delivers thermal performance that keeps your rail systems on track from the mainline to the last mile, and from conventional engines to zero-emission solutions.