Cu-Brass Heat Exchangers

- Home

- Solutions & Technologies

- Cu-Brass heat Exchangers

Cu-Brass Heat Exchangers

Durable Thermal Management for Heavy‑Duty, Off‑Highway and Industrial Applications

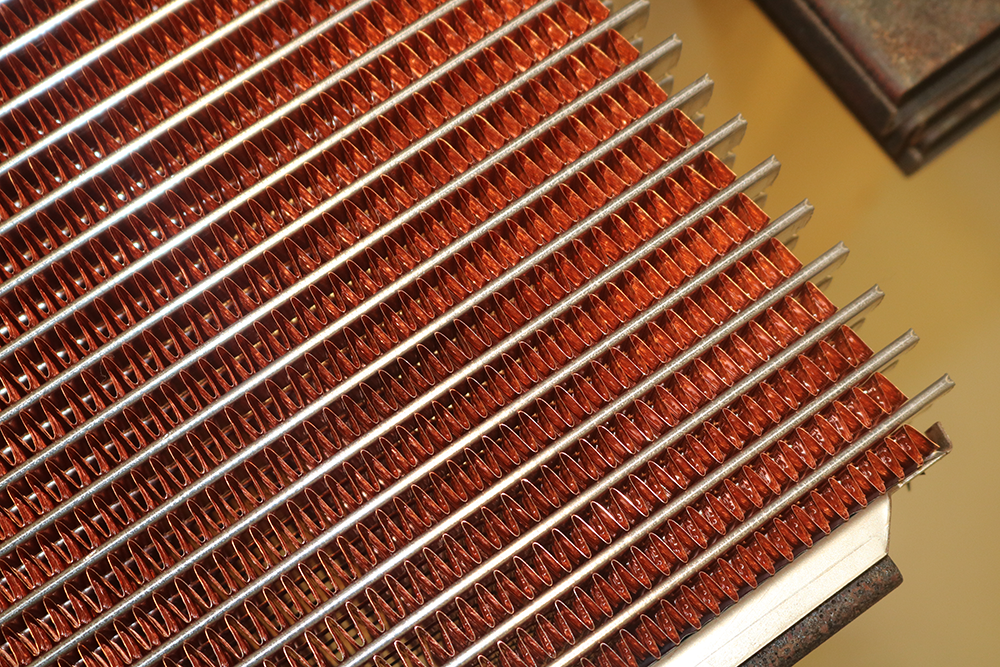

Cu‑Brass heat exchangers remain a proven choice in the most demanding thermal management environments due to the unique combination of high thermal conductivity, mechanical robustness, and reparability offered by copper‑based alloys. Designed for applications such as heavy‑duty trucks, construction and agricultural equipment, mining machinery, power generation, and other industrial systems, these heat exchangers excel where high thermal loads and extreme operating conditions are present. Constructed using brass tubes and copper fins, the architecture enables efficient heat rejection for radiators, charge‑air coolers, and oil cooling systems under severe thermal and pressure cycles. Advanced alloy metallurgy and controlled brazing processes provide exceptional resistance to corrosion, fatigue, and vibration, ensuring long service life even in dusty, high‑load, and high‑temperature environments. An important advantage of Cu‑Brass technology in these sectors is field repairability: damage to tubes or fins can be effectively repaired through soldering, minimizing downtime and extending service life without the need for full unit replacement.