How Fin Design Impacts Heat Exchanger Efficiency

Unlocking performance through thermodynamics, surface science, and smart material selection.

How Fin Design Impacts Heat Exchanger Efficiency: A Deep Dive into Radiator Engineering

In the evolving landscape of thermal management, the design of heat exchangers is no longer about simply increasing surface area. At Dolphin Manufacturing LLC, our compact heat exchanger designs are engineered from a holistic systems perspective where every fin, surface, and alloy layer matters.

We combine thermodynamic principles with material science to craft lighter, more efficient, and corrosion-resistant solutions that meet the demands of today’s industries.

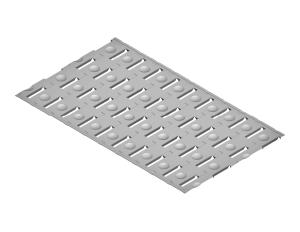

Flat fin

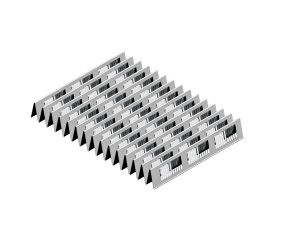

Louvered Fin

What Role Do Fins Play in Heat Exchangers?

Fins are known as secondary surfaces, working in tandem with the primary surfaces (typically tubes) to improve heat dissipation. But what exactly do they do?

The Two Key Functions of Fins:

- Increase surface area for better convection.

- Break the boundary layer to promote efficient heat transfer.

While they might seem like simple additions, fins are far more sophisticated than they appear. The effectiveness (ⴄf) of a fin isn’t determined by its size alone—it depends on how it enhances heat transfer at the tube level.

Understanding the Boundary Layer: Why Fin Design Matters

When air flows over a surface, a boundary layer forms a thin zone where heat transfer is restricted. Fins are designed to disturb this layer, improving local heat transfer coefficients. However, the farther a fin extends from the tube, the less effective it becomes.

This means that fin geometry and placement must be precisely optimized to avoid unnecessary increases in pressure drop (ΔP) while still enhancing performance.

Material Matters: Engineering Aluminum for Performance

Fins are only part of the equation. The choice of base materials, particularly aluminum, plays a central role in:

- Reducing weight through downgauging

- Enhancing corrosion resistance

- Enabling sustainable and cost-effective designs

At Dolphin, we go beyond conventional materials by employing multi-layered corrosion prevention strategies tailored for each application.

Corrosion Prevention in Downgauged Aluminum Systems

Thinner aluminum designs require precise metallurgy to ensure long-term reliability. Here’s how we safeguard durability:

Our 4-Pronged Strategy:

- Control of electrochemical potential between different materials

- Use of engineered multiclad composite systems

- Tailoring grain structure and orientation (e.g., flat platelet grains)

- Application of sacrificial band alloys in corrosion-prone zones