Manufacturing Technologies

- Home

- Industries

- Manufacturing Technologies

Manufacturing Technologies

Manufacturing Technologies: Precision and Innovation in Modern Production

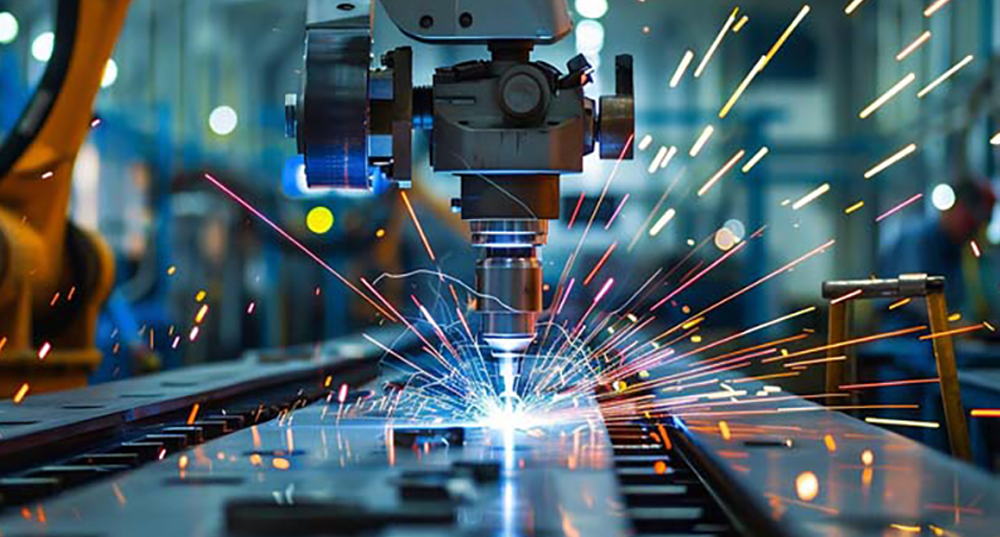

Advanced manufacturing technologies such as Robotic Welding, High-Frequency Welding, and Laser CNC Machining have revolutionized modern production by enhancing precision, consistency, and efficiency. Robotic welding ensures uniform, high-quality welds with minimal human error, increasing production speed and safety in complex assemblies. High-frequency welding is ideal for joining thin metal components, offering rapid, clean welds with strong structural integrity especially useful in applications like heat exchanger manufacturing. Laser CNC machining provides unparalleled accuracy in cutting and shaping metal parts, enabling the production of intricate designs with tight tolerances. Together, these technologies support mass customization, improve product reliability, reduce waste, and optimize throughput, making them essential in industries such as automotive, aerospace, HVAC, and heavy machinery.

High Frequency Welding (HFW)

is a highly efficient and reliable welding process used to join metallic materials primarily steel using high-frequency electrical currents. This solid-state welding technique is widely employed in industries such as oil & gas, automotive, construction, and structural fabrication due to its speed, consistency, and superior weld quality

Robotic Welding

Robotic welding is a highly advanced manufacturing process that uses automated, programmable robots to perform welding tasks with exceptional speed, consistency, and accuracy. Widely adopted in industries such as automotive, aerospace, heavy machinery, and metal fabrication, robotic welding enhances productivity by significantly reducing cycle times and minimizing human error. These systems are ideal for repetitive or complex welding operations, offering precise control over weld quality and placement.

Laser CNCs

Laser CNC (Computer Numerical Control) technology is a cutting-edge manufacturing process that combines the precision of laser cutting with the automation of CNC systems. It is widely used for cutting, engraving, and shaping a variety of materials especially metals with extreme accuracy and minimal material waste. Laser CNCs utilize high-powered laser beams guided by programmed instructions to produce intricate designs, sharp edges, and complex geometries with high repeatability.

Large and Modern Coil Fin Press

Large and modern coil fin presses are essential equipment in the high-volume production of fins used in heat exchangers for HVAC, automotive, power generation, and industrial applications. These advanced machines are designed to handle wide metal coils with high-speed precision, stamping intricate fin patterns with uniform accuracy. Equipped with automated feeding systems, servo drives, and programmable controls, modern fin presses ensure consistent quality while significantly increasing output and efficiency.