OEM Thermal Management System Design Process Workflow

- Home

- Industries

- OEM Thermal Management System Design Process

OEM Thermal Management System Design Process Workflow

OEM Thermal Management System Design Process Workflow

Our OEM thermal management system design process combines customer-specific data, advanced thermal and structural simulations, and reliability engineering to deliver optimized, validated solutions from 3D modeling to prototype and production.

Customer Data Acquisition & Requirement Definition

We begin each project with a systematic acquisition and analysis of customer‑specific inputs. This includes detailed engine and powertrain specifications, duty cycles, environmental and thermal boundary conditions, packaging constraints, and target performance criteria. These data form the foundation for a requirements document that aligns performance objectives with manufacturability, lifecycle durability, and TCO targets. Close collaboration with the customer ensures that the design intent is fully captured before moving into concept development.

Thermo-Fluid System and Structural Design

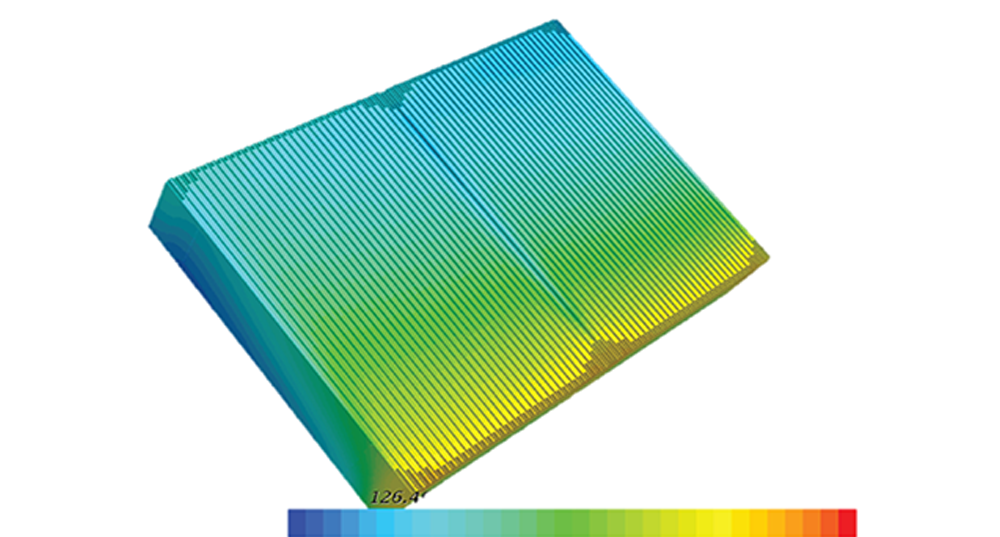

Using validated input data, our engineering team applies advanced thermodynamics and fluid mechanics to develop optimized cooling and heating circuits. Heat exchanger core geometry, water, oil, and air flow paths are sized to achieve target heat transfer rates while minimizing pressure drops across the entire operating range. Structural integrity is addressed in parallel, with load cases defined for vibration, thermal cycling, and transient pressures. This integrated approach ensures that thermal efficiency, flow management, and mechanical robustness are achieved concurrently.

Risk Analysis & Reliability Engineering

At this stage, potential risks are systematically assessed using advanced methods such as Failure Mode and Effects Analysis (FMEA) and Design for Reliability (DfR) principles. Critical factors – thermal stresses, mechanical loads, and corrosive medias – are identified early to guide material selection, joining technologies, and geometric design. This proactive approach ensures that every concept is developed with long‑term durability, safety margins, and lifecycle performance in mind, reducing the need for corrective actions later in the program.

Design Output: CAD & Prototype Development

Once the thermo‑fluid and structural concepts are validated in simulation, they are translated into detailed 3D CAD models and manufacturing drawings. These digital models form the basis for prototype builds, enabling close coordination with our manufacturing engineering teams to ensure process feasibility. Digital models and rapid prototyping techniques allow early physical evaluation and integration within the customer’s application or vehicle platform.