Optimizing Railway Heat Exchangers

Material Science Meets Thermal Management

Railway systems push heat exchangers to their limits. Constant vibrations, thermal cycles, and environmental exposure demand more than standard designs they require material science expertise and application-specific solutions. At Dolphin Manufacturing LLC, we bring decades of experience in advanced thermal management to meet these exact challenges.

Why Heat Exchanger Materials Matter in Rail System

Railway heat exchangers aren’t just about moving heat from one place to another. They operate under:

- Cyclic thermal expansion from rapid heating and cooling

- Internal pressure pulses during operation

- External shocks and vibrations from the rail environment

- Multi-axial stress due to complex system layouts

Each of these creates risks for mechanical fatigue, localized corrosion, and premature component failure. For operators, that translates into higher maintenance costs, downtime, and even disrupted fleet schedules.

The Material Science Approach

No single alloy or material system works for every application. We select and engineer materials to balance multiple performance factors:

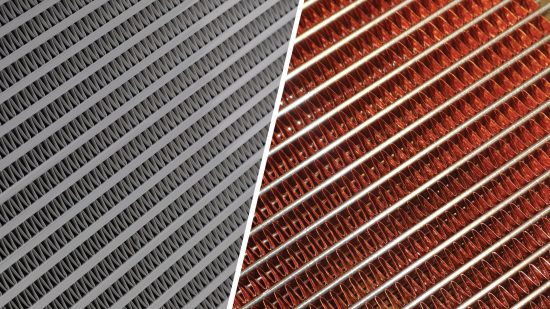

- Copper alloys (Cu & CuZn15) Known for excellent thermal conductivity but with specific corrosion considerations.

- CAB aluminum systems (Al-Mn & Al-Si) Lightweight with high corrosion resistance.

- VAB aluminum systems (Al-Mg) Excellent strength-to-weight ratio for demanding environments.

The focus isn’t on maximizing one property in isolation but achieving the right balance:

- Low-cycle vs high-cycle fatigue (LCF vs HCF) resistance

- Stress corrosion cracking vs pitting corrosion performance

Designing for Reliabilit

We take a multi-technology approach, tailoring heat exchanger designs for specific railway applications:

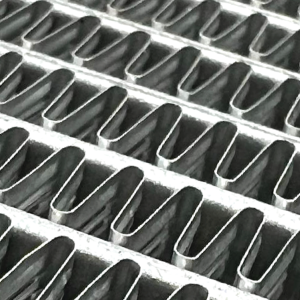

- PFRT (Plate Fin and Round Tube) Ideal for compact, high-performance cooling.

- Tube-and-Fin and Bar & Plate Aluminum Flexible designs for diverse operational needs.

- Mechanically Bonded Flat-to-Round Systems Enhanced durability in harsh conditions.

Applications include radiators, charge air coolers (CACs), HVAC&R, water/brine intercoolers (WBICs), and lube oil cooling systems.

The Total Cost of Ownership Impact

A single heat exchanger failure can mean:

- Replacement parts and logistics costs

- Increased labor hours

- Secondary equipment damage

- Unexpected downtime across fleets

By optimizing materials and designs up front, we help operators reduce these risks and improve overall system reliability.

The Dolphin Advantage

Our strength lies in combining deep application knowledge with flexible manufacturing technologies. We’re not locked to one design or alloy. Instead, we deliver solutions tailored to each client’s operating conditions and long-term performance goals.

The result: thermal

management systems that are efficient, reliable, and built for the future of rail.

Looking to enhance the reliability of your railway systems?

Explore Dolphin’s Railway Thermal Management Solutions