Battery Cold Plates

- Home

- Solutions & Technologies

- Battery Cold Plates

Battery Cold Plates

Precision Thermal Management for New Energy Systems

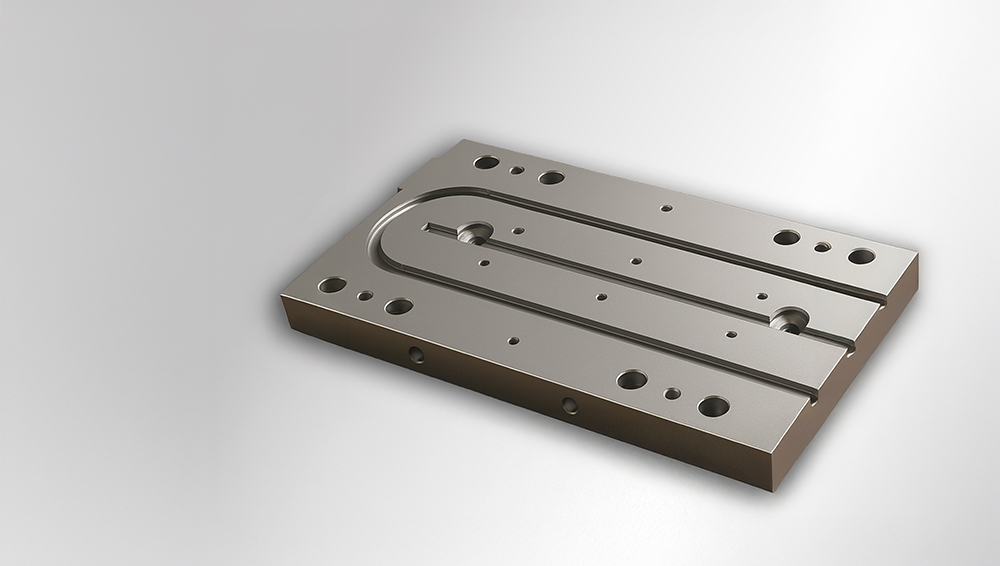

Battery cold plates are critical components in NEV thermal management systems, providing precise temperature regulation for lithium‑ion and next‑generation battery chemistries. By circulating coolant through channels integrated within lightweight, high‑conductivity aluminum or copper plates, they maintain battery cells within an optimal temperature window, which is essential for safety, charge/discharge efficiency, and long‑term durability. This technology is applied across a wide range of sectors, including on‑highway electric and hybrid vehicles, off‑highway machinery, rail traction systems, and stationary energy storage units. Advanced designs ensure uniform temperature distribution across large cell arrays, mitigating hotspots that can lead to accelerated aging or thermal runaway. Through optimized alloy metallurgy and controlled manufacturing processes, cold plates can be engineered to perform not only as a heat exchanger but also as a structural component, contributing to overall battery pack stiffness and crashworthiness while minimizing weight. Using computational fluid dynamics (CFD) and finite element analysis (FEA), both the internal flow paths and the structural geometry of the plates are optimized for thermal performance, pressure drop, and mechanical integrity under demanding duty cycles. This integrated approach enables higher power density, increased reliability, and extended lifecycle of batteries in mobility and stationary applications.